|

|

|||||||

| 1973 to 1985 Carburated Vehicles Emissions laden vehicles, but still simple enough to work on and we still love 'em! |

|

|

|

Thread Tools | Display Modes |

|

#1

|

||||

|

||||

|

My dad ended up getting this about a decade ago from one of his friends for only the price of taking it off of the property.

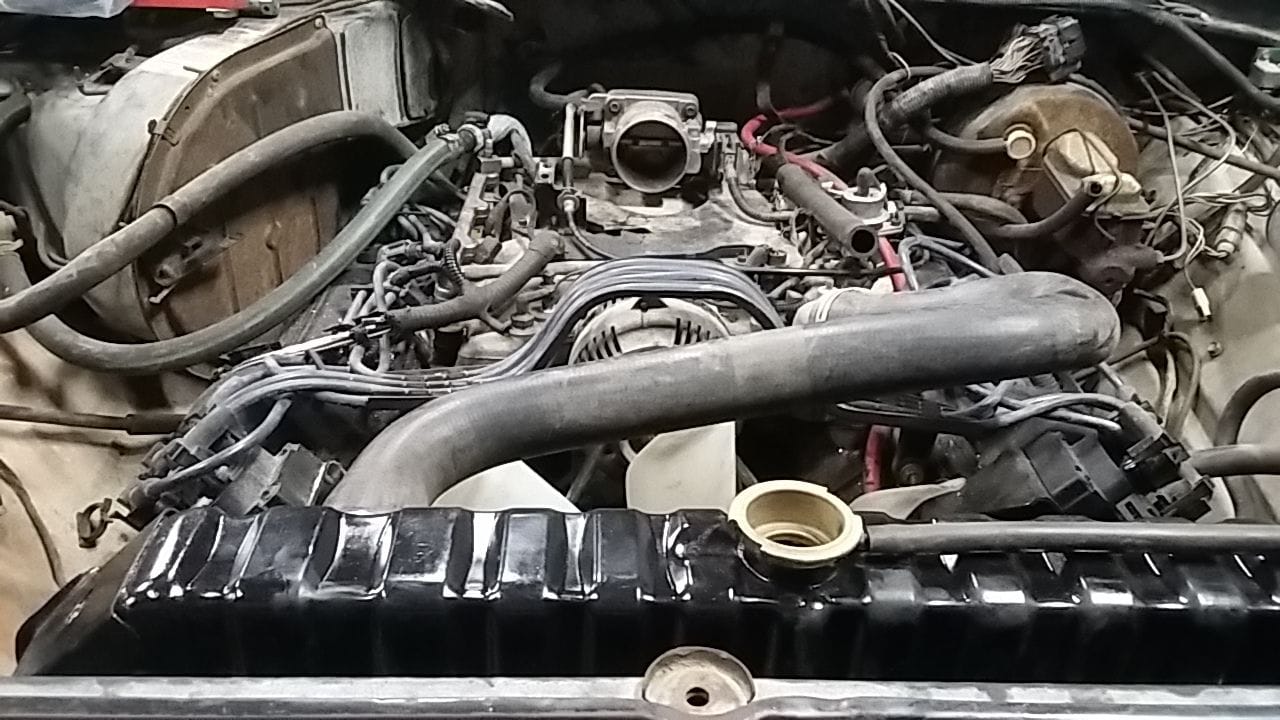

Dad got it running, put a tank and pump unit on it, and we use it for fire suppression on our property (and adjacent landowner property) as kind of a first responder deal. The 390 was tired (well, is....it's sitting in a shed waiting for a rebuild) and my wife can't drive a manual (I know, what was I thinking?) so I thought, "Hey, I've got a perfect-running 4.6L and AODE sitting in the shed that was originally out of my now 7.3L-powered Crown Victoria. It's a little gutless in high range but it won't be a highway rig anyway. It lives in low range around here which is good enough for 45 MPH gravel roads. I'll just put up pictures. Any specifics can be answered. Last edited by cleatus12r; Sun, December 20th, 2020 at 11:51 PM. |

|

#2

|

||||

|

||||

|

|

#3

|

||||

|

||||

|

It's amazing how well those tuck right into older vehicles. That's a really nice setup.

How many radiator hoses did you have to go through to get the orientation you needed? What major problems did you encounter? I see the motor mount brackets and the cut driveshaft. Anything else significant?

__________________

Bill Cohron - The Mad Doctor    Power Hungry Performance - The ORIGINAL in Ford performance tuning... Since 1997! (678) 890-1110 www.gopowerhungry.com - Home of the Hydra Chip, Minotaur Tuning Software, and the new Orion Reflash System for Navistar! Bring back  Windows™ XP and 7. Windows™ XP and 7.   Windows™ Vista and Windows™ Vista and  Windows™ 8 is a pain in my a$$! Windows™ 8 is a pain in my a$$!   Windows™ 10 is only slightly less annoying! Windows™ 10 is only slightly less annoying!   Windows™ 11 is garbage! Windows™ 11 is garbage!  Much to my surprise, I'm actually quite enjoying Linux!

|

|

#4

|

||||

|

||||

|

Quote:

The upper hose is a stock mid-90's F150/5.0 hose and the lower is a factory Crown Vic hose just shortened across the bottom and spliced together with exhaust pipe. I'd like to put a shroud of sorts on it but the top of the fan is even with the bottom of the top tank. The driveshaft between the transmission and transfer case is a the stock 'Vic slip yoke unit cut down and welded to the original F-250 yoke at the transfer case. The tube diameter and thickness were identical so it was easy to chuck up in the lathe at work, square-up, and weld. The only other real challenge was making a shift linkage bellcrank that was the correct "ratio" for the AODE lever so it would match up with the indicator on the column. Otherwise, business as usual. The exhaust is ridiculously loud and snappy too - 2" pipe with no mufflers into the stacks. Of course the tuning has been modified as to make it shift really good! |

|

#5

|

||||

|

||||

|

So the question is, did you cab-off the install? This is what I'm getting ready to do with my '64 since I'm going to need to completely fab up new crossmembers for the front and rear.

The older Med Duty trucks reversed the mounting triangle with 2 mounts on the trans and a single one on the engine. This does have some advantages, like when having to pull the transmission out, since the transmission is basically free-hanging off the bellhousing. Putting in the new FE block mated to a T56 Magnum is going to really mess all that up, so I'll need to build new front mount pedestals along with a normal trans crossmember. Nice thing is I can build it all as a tubular setup with plates and then bolt it to the frame.  The only other thing I'll need to address is the need for a PTO for the dump bed. I was thinking of an electric motor to run the "pump" for the lift, but I may just go with a hydraulic master/slave setup. Because the lift has the pump built into it, I may have to get creative. Anyway, just curious how that went.

__________________

Bill Cohron - The Mad Doctor    Power Hungry Performance - The ORIGINAL in Ford performance tuning... Since 1997! (678) 890-1110 www.gopowerhungry.com - Home of the Hydra Chip, Minotaur Tuning Software, and the new Orion Reflash System for Navistar! Bring back  Windows™ XP and 7. Windows™ XP and 7.   Windows™ Vista and Windows™ Vista and  Windows™ 8 is a pain in my a$$! Windows™ 8 is a pain in my a$$!   Windows™ 10 is only slightly less annoying! Windows™ 10 is only slightly less annoying!   Windows™ 11 is garbage! Windows™ 11 is garbage!  Much to my surprise, I'm actually quite enjoying Linux!

|

|

#6

|

||||

|

||||

|

Just pulled the front fenders and core support. I did it that way because I knew that I wanted to put the engine and transmission in as one unit and that I would have to do engine mount work. The original NP435 transmission mount and crossmember were used and only two holes had to be drilled.

Is your intended transmission bellhousing made of steel? Most of the car shows I have seen where a fancy 5/6 speed transmission is installed use a stamped steel bellhousing and I don't know why a guy couldn't weld mounts to it that would coincide with the frame mounts. As far as the PTO is concerned, you might have issues with a 12V system. As you're aware, it's not really possible to get a high horsepower motor with a 12V system due to the immense current draw. Installing a few bale beds with electric/hydraulic setups along with a few snow plows having cylinders with a maximum of 2" diameter has proven that those motors just about max-out most 2-4/0 cables and charging systems. Add in that the volume required to move a (I'm guessing) 4" or larger hydraulic cylinder with a tiny pump will take eons to lift. |

|

|

|